Products

A Comprehensive Portfolio of High-Performance Aerostructure Products

At MRAS, we are committed to providing our customers with the highest quality aerostructure solutions. Our team of experienced engineers and technicians is dedicated to understanding your specific needs and exceeding your expectations. Let MRAS be your partner in innovation and help you achieve your aerospace goals.

MRAS offers a diverse range of aerostructure products that meet the demanding requirements of aerospace applications

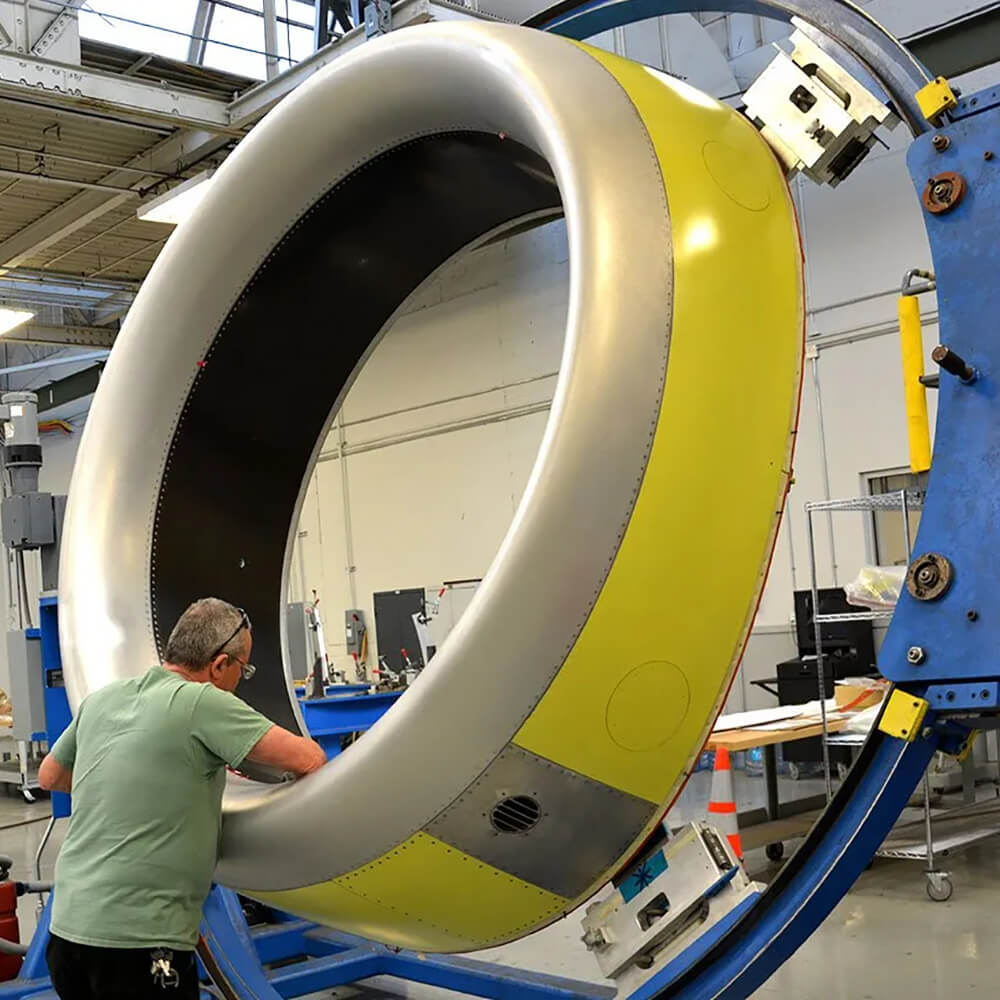

Complex Structures

Mastering Aerospace Complexity: MRAS Expertise in Complex Structures

MRAS is a recognized leader in the design, development, and manufacturing of complex aerospace structures. With over nine decades of experience, MRAS has established a reputation for innovation, quality, and reliability. The company’s team of highly skilled engineers and technicians leverages their in-depth knowledge of advanced materials and manufacturing technologies to deliver exceptional products that meet the stringent requirements of the aerospace industry.

- Commercial and Military Nacelle Components: From thrust reversers and inlets to fan cowls and inner fixed structures, MRAS provides a comprehensive suite of nacelle components for both commercial and military aircraft.

- Aircraft Empennages and Structural Components: Our expertise extends to the design and manufacture of lightweight and durable aircraft empennages and flight control surfaces, as well as various components of the aircraft wings such as the leading and trailing edge assemblies

- Rocket and Missile Structures: MRAS has a proven track record of delivering high-precision structural components for rockets and missiles, ensuring optimal performance and reliability meeting the stringent mission requirements of defense and space industry

- Engine Build Units: MRAS provides integrated engine build units for a variety of aerospace applications, ensuring the seamless assembly and testing of critical engine components.

- Exclusive Nacelle System Solutions: MRAS develops and supplies exclusive nacelle system solutions to leading aerospace engine manufacturers, partnering with them to create innovative and efficient nacelle systems.

- Integrated Propulsion Systems (IPS): Through our Nexcelle joint venture with Safran Nacelles, MRAS delivers fully integrated propulsion systems solutions that optimize the performance and efficiency of aerospace propulsion systems.

MRAS’s reputation for quality and innovation has earned us the trust of industry-leading aerospace companies worldwide. Explore our extensive range of products and discover how MRAS is powering the future of aerospace.