MRO

MRAS, a division of ST Engineering operates a 100,000 sq. ft. state-of-the-art maintenance, repair, and overhaul (MRO) facility with extensive capabilities and leverages our over 95 years of history including composite materials expertise and jet engine nacelle manufacturing programs.

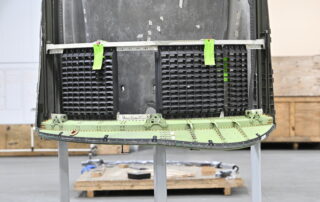

MRAS applies the skills we perfected as an OEM (original equipment manufacturer) for nacelles and thrust reversers, covering most major commercial airframes and engines to design and operate our MRO shop.

MRAS has a long history of being an industry resource and is an expert in composite and metal bonding design, manufacturing and repair.

MRAS MRO Highlights

- FAA/EASA Part 145 Repair Station MYER988K and can provide maintenance, repair, and overhaul of nacelle systems for: A320neo (LEAP-1A), 787 (GEnx & T1000), CF6-80C2 reversers (all models), CF6-80E1 reversers, A320 (CFM56-5B & V2500), 737 (CFM56-7B)

- Special projects. MRAS accomplishes PIP 2 (Performance Improvement Package) work in our repair station on major engine OEM projects to upgrade engines to the latest configuration.

- Experts in grinding of composite material around the fan case interior and rebuilding to airframe & engine OEM requirements.

- 1000 employees based in our Middle River MD facility including Engineers, Fabricators, Assemblers, Technicians and Nacelle and Structures Experts.

- ST Engineering’s global footprint supports the world in Nacelle MRO care.